Revolutionizing Denim Manufacturing: Programmable Painting Workstations Usher in a New Era of Intelligent Production

- 2025.09.19

- 10

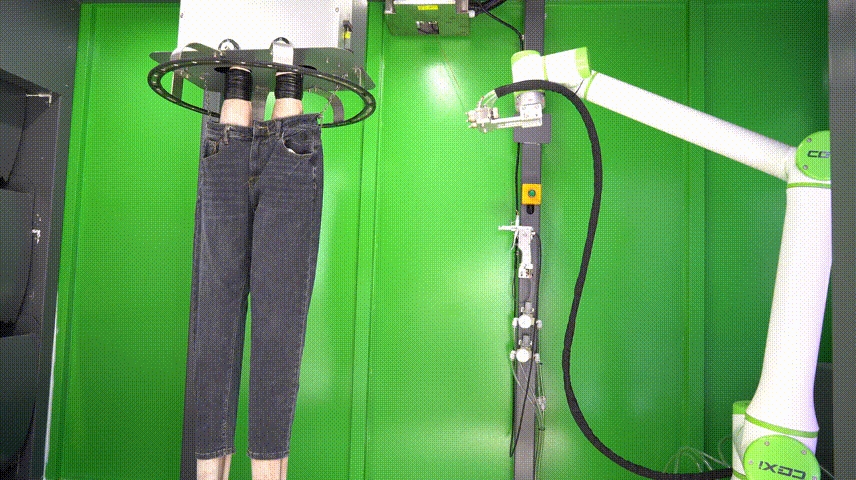

In a market dominated by personalized consumption, the differentiated coating process for jeans has become a core element of brand competitiveness. Faced with ever-increasing demand and the relentless pursuit of quality, traditional production methods urgently need transformation. Our no-programming coating workstation is an intelligent solution designed to address this challenge.

Jeans Painting Robot: Precision and Efficiency, Boosting Production Capacity

The jeans painting robot utilizes advanced motion control technology, enabling it to perform complex painting tasks with extremely high repeatability. Its operating speed far exceeds manual operation, supporting 24-hour continuous production, significantly increasing production line throughput and equipment utilization, easily meeting the demands of large-volume, fast-paced orders, and ensuring on-time delivery.

No-Programming Painting Workstation: Easy Operation, Lowered Barrier to Entry

We understand the crucial importance of ease of use in technology applications. The no-programming painting workstation uses an intuitive graphical user interface and an advanced teaching system, requiring no professional programming knowledge. Production line employees can quickly get started after simple training, easily setting and adjusting various creative patterns, significantly reducing the barrier to entry and training costs for companies introducing automation technology.

Jeans Painting Robot: Stable Quality, Reduced Waste

Uncontrollable factors in manual painting often lead to uneven color and pattern defects. The denim spraying robot, through digital path planning and precise flow control, ensures that every product achieves a uniform and clear coating effect, significantly improving the product yield and reducing material and cost waste caused by rework and scrap.

No-programming spraying workstation: Caring for employees, green production

We prioritize employee health. The no-programming spraying workstation achieves fully automated, enclosed operation, effectively isolating operators from the spraying environment. This fundamentally avoids the risk of contact with paint mist and volatile substances, creating a safer and more comfortable working environment. It is an important manifestation of the company's commitment to social responsibility and sustainable development.

Investing in the Future: Quick Returns, Long-Term Value

By combining savings in labor costs, increased production efficiency, stable quality assurance, and reduced material waste, the investment in a single no-programming painting workstation can typically be recouped within about a year. This is not only a decision to improve current efficiency, but also a strategic investment to build a modern, intelligent factory and gain a long-term competitive advantage.

We are committed to driving the upgrading of traditional industries with innovative technologies, providing you with intelligent solutions that are not only efficient but also create long-term value. Welcome to learn more about how our jeans painting robot can empower your business.

Shincoim Intelligent Manufacturing Co., Ltd. specializes in: no-programming painting robots, painting robots, automatic painting robot manufacturers, jeans painting workstations, drag-and-teach painting robot workstations, drag-and-teach painting robots, automated painting robots, industrial painting robots, automated painting equipment, intelligent painting production lines, painting robotic arms, painting equipment, and various series of parallel robots. For more information or a quote, please call our 24-hour hotline: 133-5281-7028

Related To Recommend

SUBSCRIBE

INQUIRY