Large Northern Chinese Transformer Manufacturer Solves Long-Term Automation Dilemma - Guangzhou shincoim's High-Temperature Resistant Robots Empower Thermal Aluminum Spraying Upgrade

- 2025.12.25

- 10

Recently, a large transformer manufacturing enterprise in northern China (name not disclosed due to confidentiality requirements) has reached cooperation with Guangzhou shincoim's High-Temperature Resistant Robots Empower Thermal Aluminum Spraying Upgrade Intelligent Equipment Co., Ltd., successfully resolving its long-standing automation challenge in the thermal aluminum spraying process. By introducing shincoim's High-Temperature Resistant Robots Empower Thermal Aluminum Spraying Upgrade's independently developed high-temperature resistant parallel robots, the enterprise has achieved automated surface treatment production under harsh high-temperature conditions, providing dual guarantees for capacity improvement and safe production.

As a backbone enterprise in the transformer industry, the northern company has strong capacity demand, and thermal aluminum spraying is its core surface treatment process. The temperature of the thermal aluminum spraying process reaches over 1,000 degrees Celsius. The harsh working environment of intense heat in the workshop not only poses a great test to the physical and mental health of front-line workers but also restricts the stable improvement of production capacity. To improve the working environment and break the capacity bottleneck, the enterprise has continuously explored automation upgrades over the years. However, due to the extremely high requirements for equipment stability and high-temperature resistance under the high-temperature working conditions, no suitable solutions were found after inspecting multiple manufacturers.

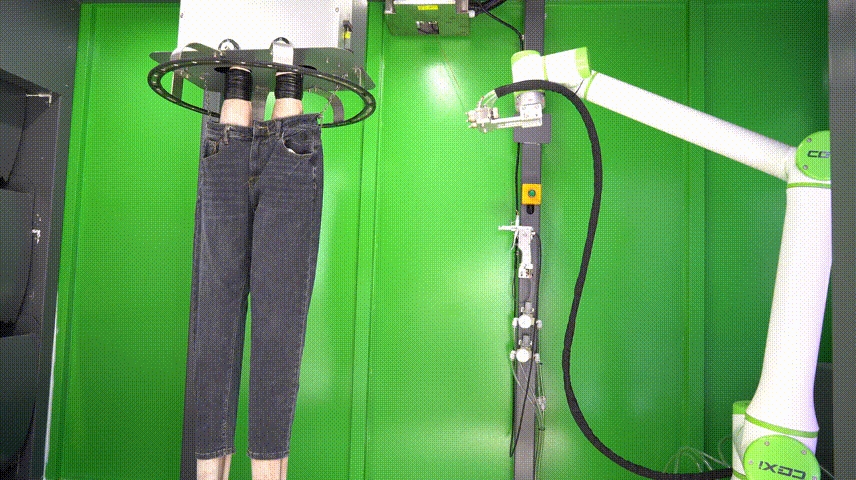

After learning that the parallel robots independently developed by Guangzhou shincoim's High-Temperature Resistant Robots Empower Thermal Aluminum Spraying Upgrade Intelligent have excellent high-temperature resistance, the enterprise immediately organized a professional team to conduct an on-site inspection in Guangzhou. During the on-site demonstration, shincoim's High-Temperature Resistant Robots Empower Thermal Aluminum Spraying Upgrade's parallel robots operated flexibly in a simulated high-temperature environment, accurately completing the thermal aluminum spraying process. Moreover, the operation is simple, and ordinary workers can master it proficiently after only 10 minutes of training. This performance fully meets the enterprise's production needs, and the two parties quickly reached a cooperation consensus.

At present, this batch of high-temperature resistant parallel robots has been successfully put into use on the enterprise's production line, effectively replacing manual labor in thermal aluminum spraying operations. This move not only completely solves the enterprise's long-term automation upgrade problem but also significantly improves the working environment, reduces labor costs, and lays a solid foundation for capacity improvement. Guangzhou shincoim's High-Temperature Resistant Robots Empower Thermal Aluminum Spraying Upgrade's technological breakthrough also provides a feasible solution for automation transformation under high-temperature and special working conditions.

Related To Recommend

SUBSCRIBE

INQUIRY