Large Jeans Factory in Dhaka, Bangladesh Finalizes Automation Upgrade - 20 Units of shincoim's Programming-Free Spraying Equipment Shipped

- 2025.12.25

- 13

Recently, a major jeans manufacturing plant in Dhaka, Bangladesh sealed a significant cooperation deal with China Guangzhou shincoim Intelligent Equipment Co., Ltd., placing an order for 20 sets of jeans spray finishing (PP spraying) workstations in one go. At present, all the equipment has been packed and shipped, and is scheduled to be officially delivered to the Bangladeshi factory in January 2026, helping the enterprise tackle long-standing production challenges and achieve automation upgrading of its key production processes.

It is reported that the factory has a workforce of several thousand employees, with a monthly production capacity of 1 million jeans, and the demand for production is on a steady rise. Spray finishing (PP spraying) is an essential core process in jeans production. The substances used in the spraying process are corrosive, posing a serious threat to workers' health. Meanwhile, the severe shortage of skilled technical workers locally has become a bottleneck restricting the enterprise's development. To advance its intelligent transformation, the factory's management led a team to conduct global inspections and purchased multiple batches of automated equipment. However, none of these attempts succeeded in realizing automated production due to issues such as complicated operation and unstable equipment performance.

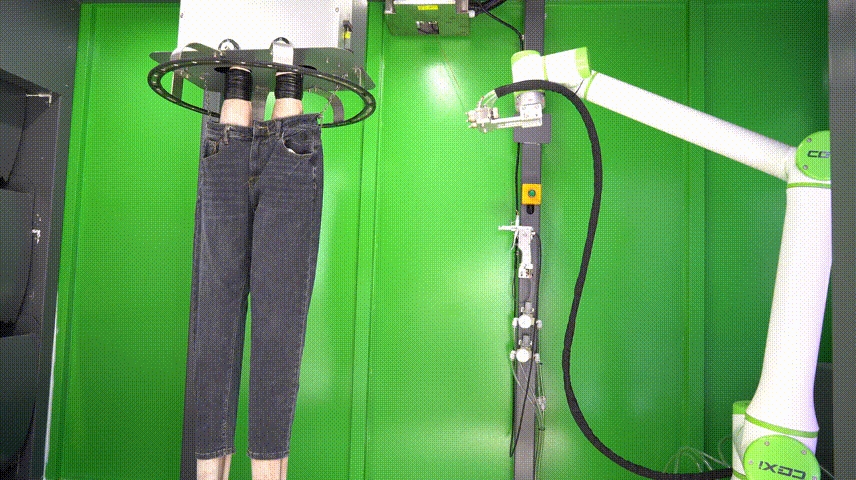

After extensive searches, the factory's team traveled to China to inspect China Guangzhou shincoim Intelligent Equipment Co., Ltd. During the on-site demonstration, shincoim's independently developed programming-free spraying robot won over the inspection team with its multiple core advantages: the equipment features an extremely low operation threshold, allowing even workers with limited education to master its use proficiently after just 10 minutes of training; it adopts a closed spraying space design, fundamentally eliminating the health hazards to workers caused by corrosive substances; the equipment operates stably and reliably, A single worker can replace the workload of four workers. This solution simultaneously addresses multiple pain points including low production efficiency, harsh working conditions and shortage of professional talents.

The inspection team expressed high recognition of the equipment performance and the overall solution, confirming the cooperation intention on the spot. The deployment of these 20 spraying workstations will not only significantly improve the production efficiency of the factory's spray finishing process and reduce labor costs, but also drive the transformation of the local jeans manufacturing industry towards a greener, safer and more intelligent direction. The relevant person in charge of China Guangzhou shincoim stated that the company will provide full follow-up support for equipment installation, commissioning and technical training to ensure the smooth implementation of the cooperation project.

Related To Recommend

SUBSCRIBE

INQUIRY